Project #:

H19-E001

Project Type:

Equipment Training and Support Services

Project Date:

2019-05-20

Our team in

Northern Cape Haitian District, Haiti

are thankful for the generous support of

Benefaction Foundation

(Toronto, ON)Pitchfork BBQ & Supper in the Country Attendees

(Bow Island & Medicine Hat, AB)Waifs Worldwide Trust

(North Vancouver, BC)for helping provide

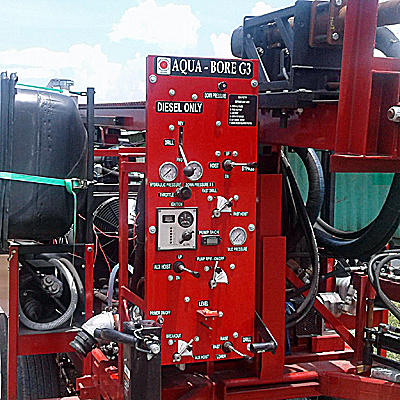

Aqua Bore G2 UD-Super Diesel Mud Rotary

to aid their work and transform lives

A message from the community

Dear Madame/Sir: On behalf of the entire team I wish to extend to you their excitement and thanks for this new rig. We have been struggling for some time with our older drill rig as parts are no longer available. The down time to make needed repairs causes a great deal of down time and the wells are not being drilled to the people in need. This new rig changes everything and everyone is looking forward to the chance to reach out to do more drilling and get more water flowing freely to our nation. Thank you for making that possible Hanania Orelus Program Coordinator

Some community details (provided by our in-country partners)

There were two mud rotary drill rigs in Haiti. One was nearly 30 years old and experiencing ever-increasing breakdowns. The other was a homemade unit that was donated to Lifewater but lacked durability and part availability. The down time to make needed repairs is idling the teams more and more frequently. This stops wells from being drilled for those suffering from lack of safe drinking water. The new Aqua Bore machine is a compact, powerful and full featured water well drill rig capable of drilling over 450 ft. through all types of formations. It comes mounted on a dual axel trailer to help it travel over poor quality roads. The new rig has a big diesel engine giving it lots of power to drill deep and even penetrate hard coral layers the current rigs cannot penetrate. The rig controls and hydraulic assists allow the drillers to work much more safely. With retractable mud pans, high efficiency mud pumps and powerful push-pull power, this rig can quickly be set-up and drill a well to completion. The robust, new components mean that there should be few breakdowns in the years ahead. These factors all combine to inspire hope for the Haitian team that they will be able to drill more wells than ever before, providing countless cups of cold water to those in need. SPECIFICATIONS The Aqua Bore G2 UD-Super Diesel Rig included the following accessories: 10,000 pound GVW Tandem Axle transport kit with pipe storage;industrial 84HP Kubota diesel power unit driving all hydraulic systems;Control panel that includes VS flow settings, mud pump clutch, primer valve and mud flow valves all at this one station for excellent operator control and safety;High rise accessory jib;100 pitch roller chain hoist for 12,000 push pull for main host;3x2 mud pump with 30 HP hydraulic drive motor allowing for up to 130 PSI and 240 GPM flow for the best drilling results;12 volt electric primer;Hydraulic ram breakout system;11.5ft. head travel for 10 foot drill rodsIt was outfitted with the following options to make it optimal for continous use in Haiti: Transport kit 10,000 GVW with pipe trays;300 Gal. carry-on drop down mud pit system;Pipe handling jig;Inductor mud mixer;Borehole thimble kit system;Ground anchor kit;Mayhew Junior to 2-7/8” box to box API sub adapter;Large lockable HD steel tool box;On board hydraulically powered development compressor;5 5/8” PDC bit for drilling hard rock;Maintenance Kit; Seals for swivel, bearings for swivel;Mud pump packing sets;Hydraulic oil filters, Engine filter sets;Engine oil for 2 changes, Compressor oil for two changes;Extra mud pan, air piping and valves;Assorted wrenches, hoses, fittings, grease and grease gun, pipe wrenches and more;Spare reversible chrome moly ware sleeves for the swivel head

What It's All About - Newly drilled Water Well

Unloading Rig at Haiti Compound

Side view showing Pipe Rack